Reduce Risk, Extend Service Life, Cut Costs

Continuous SHM that protects infrastructure, cuts maintenance spend, and prolongs asset life. Sentra pairs high-fidelity sensors, edge gateways, and powerful analytics to make sensor data instantly actionable.

Overview

At Sentra, we help infrastructure owners, contractors, and operators monitor the health of structures through purpose-built IoT systems. From deploying GNSS meters and tilt sensors to running edge AI for instant anomaly detection and feeding digital twin dashboards, we deliver an end-to-end service tailored to your asset type and risk profile. Whether you need short-term construction monitoring or permanent asset surveillance, our solutions scale from single-structure deployments to city-wide sensor networks.

Solution Demo

What's Included

Practical, deployment-ready components and services that make SHM useful from day one. Below is our standard SHM package — designed for railway bridges (concrete, steel, composite) and tailored to each site.

- Site survey & SHM program design

- Sensor Provisioning & Professional Installation

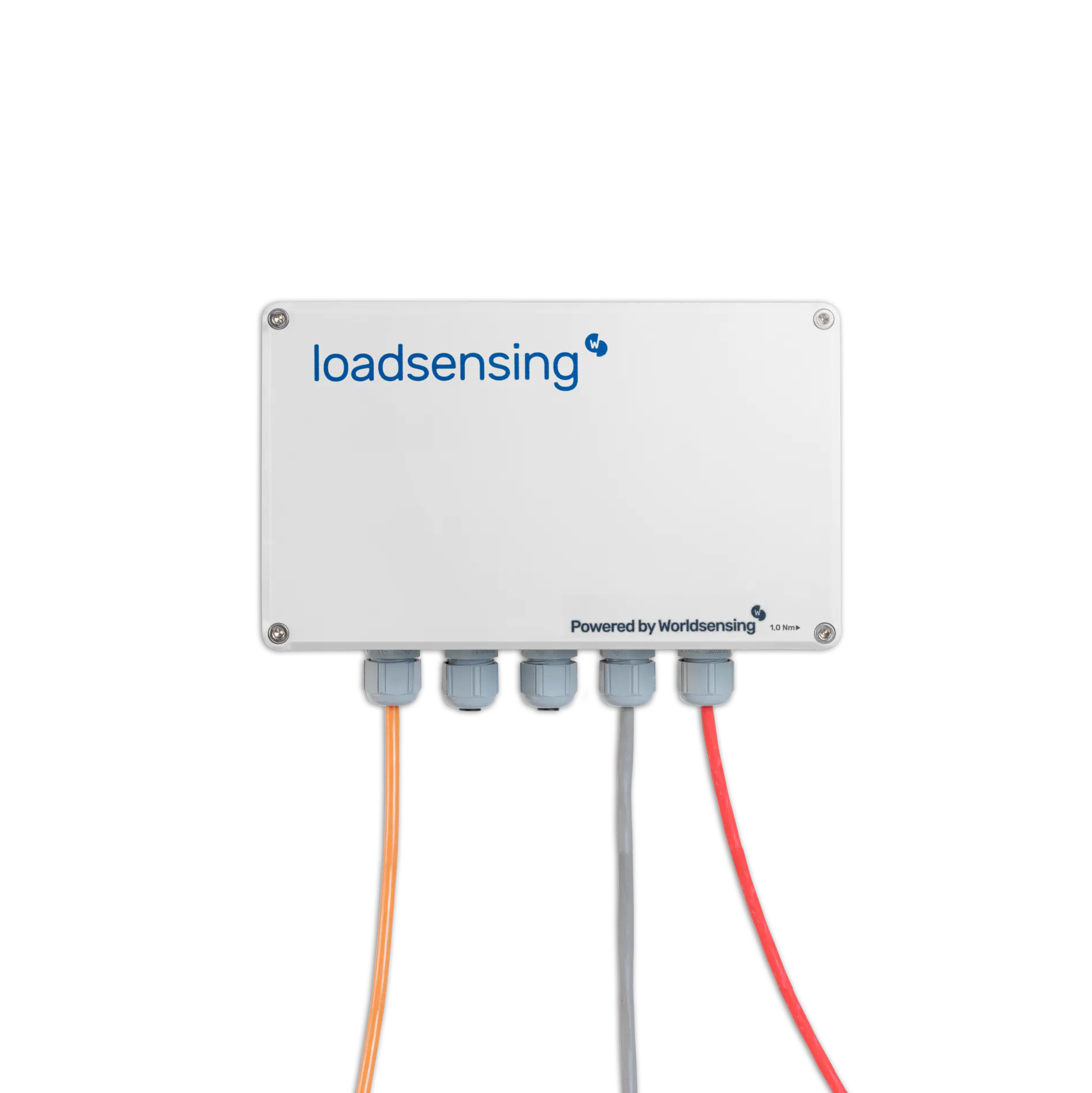

- Edge-enabled Data Acquisition & Secure Gateways

- Real-time analytics, Alerting & Dashboards

- Digital twin & Visualization

- Predictive Maintenance & Machine-learning models

- Periodic reporting & Operational support

Why Choose Us for Structural Health Monitoring?

Practical reasons that matter to infrastructure owners and engineering teams.

Result‑Driven Monitoring

Early detection and prioritized interventions

Engineered Accuracy

High‑fidelity GNSS, tilt, and Vibration sensors

Edge Intelligence

Low‑latency anomaly detection, fewer false positives

Actionable Reporting

Real‑time alerts, and integrations with asset management systems

Best in Class Products

200+

Satisfied Clients

Don’t Trust Us, Trust Their Voice

Discover how your projects achieve maximum visual impact with Sentra's expert SHM solutions.

Got Questions? We've Got Answers.

We deliver end-to-end Structural Health Monitoring services: site survey & risk assessment, custom SHM program design, sensor procurement and professional installation, edge-enabled data acquisition and secure gateways, 24/7 real-time analytics and alerting, digital-twin visualization, predictive maintenance models, monthly performance reports, system integration with asset management/SCADA, and ongoing operational support.

You’ll see useful sensor readings and basic alerts as soon as sensors are installed and connected (hours–days). Actionable trends and a reliable baseline typically emerge within 2–6 weeks of continuous data collection. Advanced predictive models and full digital-twin calibration generally require 2–6 months of data depending on site complexity and traffic/environmental cycles. We recommend a short pilot (4–8 weeks) to validate measurements and tune thresholds before full rollout.

Yes. We design scalable SHM solutions for single-span bridges up to large multi-site railway networks. Small projects can start with a targeted pilot; large asset owners receive enterprise-grade deployments with multi-site dashboards, role-based access, and integration options. Solutions are tailored to budget, regulatory needs, and technical resources.

Absolutely. All installations are customised — from sensor types and sampling rates to analytics, reporting cadence, and integration with your systems. Our process: site survey → risk & scope definition → modular proposal → pilot (optional) → full deployment. Custom packages include documentation, test plans and handover training.

We recommend starting with a technical site survey and risk assessment. That tells us the structure’s failure modes (fatigue, corrosion, cracking), critical components to monitor, and the sensor mix required. From there we propose a focused pilot or full program based on your objectives: safety assurance, long-term performance tracking, regulatory compliance, or cost-optimised maintenance.

Yes. Standard deliverables include a monthly report with an executive summary, sensor health and uptime, trend plots (strain, displacement, vibration, temp), identified anomalies, recommended actions and maintenance prioritisation, plus a downloadable CSV of key metrics. Custom reporting frequency (weekly/quarterly) is available.