Precision Monitoring for Concrete Infrastructure

At Sentra, we specialize in advanced structural health monitoring solutions, particularly for concrete-based infrastructure. Our Vibrating Wire RCR (Remote Connectivity Recorder) is engineered to deliver real-time insights into the stress and strain of tunnel linings and precast concrete segments, starting from the manufacturing stage.

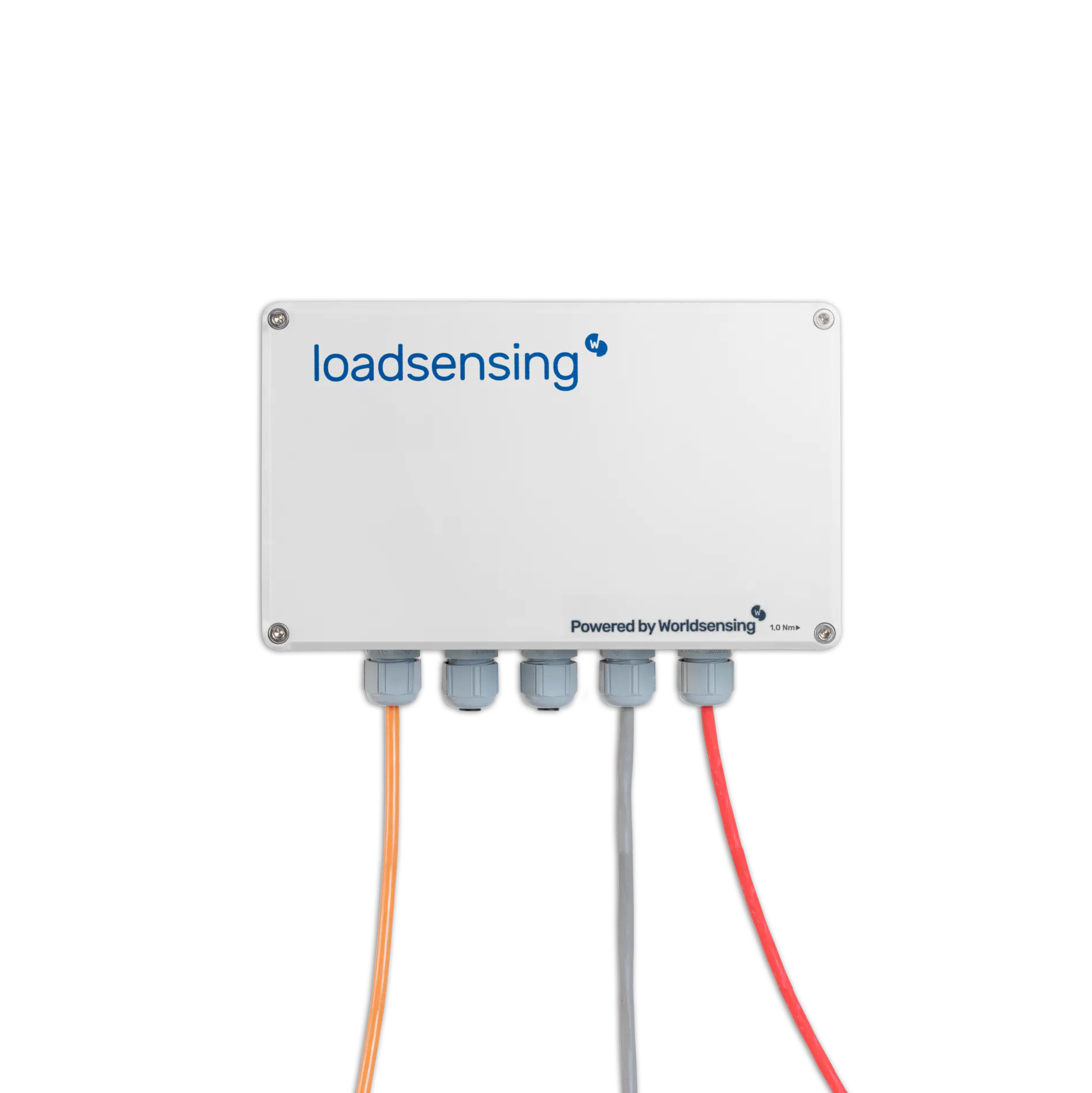

Vibrating Wire RCR

Embedding in precast concrete segments.

Securely connects vibrating-wire sensors

Up to ~3 km for line-of-sight/installation networks.

22.7 years @ 1-hour reporting; >25 years @ 6-hour reporting.

Overview

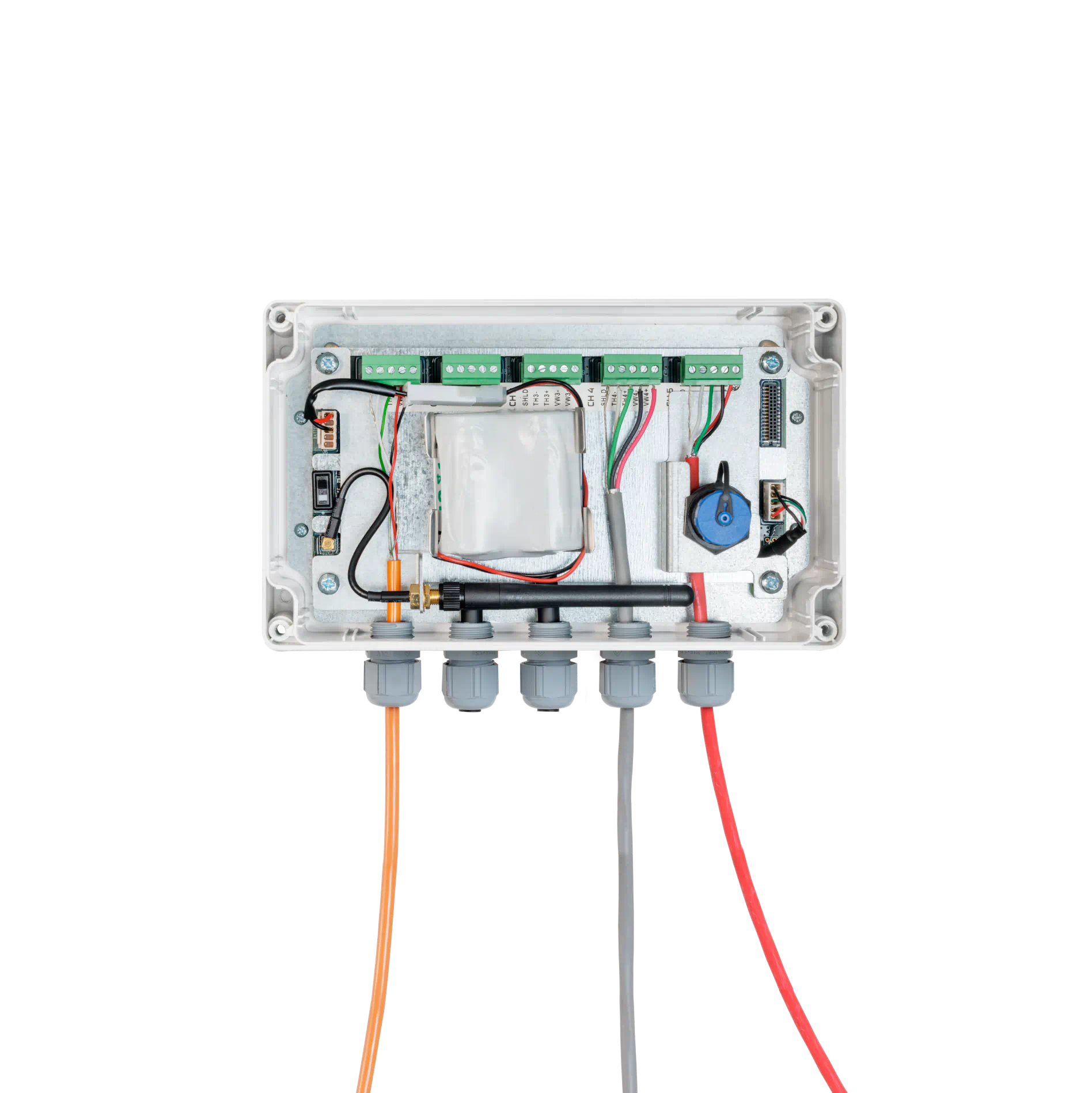

The Vibrating Wire RCR is a robust, wireless data acquisition device designed for long-term monitoring of concrete and structural assets. It continuously records stress, strain, and pressure from vibrating wire sensors, providing real-time insights without the need for manual readings. With edge-level data validation and threshold-based alerting, the system ensures that critical structural changes are detected early, supporting proactive maintenance and reliable decision-making.

What's Included

Complete, deployment-ready components and services designed for immediate and reliable structural monitoring.

- Vibrating Wire Data Logger

- Long-Term Wireless Connectivity

- Durable Concrete-Ready Design

- Edge-Level Data Validation & Alerts

- Local Data Storage & Redundancy

- Device Setup & Configuration Tools

- Reporting & Performance Insights

Prevent Structural Failures Before They Happen

Practical reasons that matter to infrastructure owners and engineering teams.

Result‑Driven Monitoring

Early detection and prioritized interventions

Engineered Accuracy

High‑fidelity GNSS, tilt, and Vibration sensors

Edge Intelligence

Low‑latency anomaly detection, fewer false positives

Actionable Reporting

Real‑time alerts, and integrations with asset management systems

Main technical specifications

| Input Types | Vibrating wire and thermistor per channel |

|---|---|

| Memory | 73,500 readings |

| Vibrating Wire | |

| Measurement Method | Embedded algorithms increasing immunity to noise |

| Excitation Wave | ±5 V |

| Measurement Range | 300 to 7000 Hz |

| Accuracy | From 0.008% to 0.013% (depending on frequency sweep range) |

| Resolution | < 0.01 Hz (depending on frequency sweep range) |

| Thermistor | |

| Measurement Range | 0 Ω to 4 MΩ |

| Resolution | 1 Ω |

| Accuracy (20°C) | 0.05°C (0.04% FS) |

| Battery Life Estimations | |

| Reporting Period – 5 min | 4.6 years |

| Reporting Period – 1 h | 22.7 years |

| Reporting Period – 6 h | > 25 years |

Got Questions? We've Got Answers.

It’s a wireless tri-axial sensor for continuous vibration monitoring of structures like bridges, tunnels, railways, and buildings — helping detect vibration events, assess structural health, and ensure safety compliance.

The sensor uses a 3-axis MEMS accelerometer with an edge algorithm that identifies threshold breaches based on Law/PPV and frequency, ensuring only critical vibration data is reported.

It supports LoRaWAN and 4G LTE, enabling long-range, low-power communication — up to 10 km coverage using repeaters, even in underground or remote environments.

With its ultra-low-power design, the replaceable battery lasts up to 1.5 years under normal operation, ensuring reliable long-term deployment.

Yes. It’s fully compatible with Worldsensing’s Loadsensing network, allowing seamless integration with CMT platforms, dashboards, and digital twin systems for real-time visualization and analytics.

It can be installed on bridges, tunnels, buildings, industrial machinery, and construction sites, including underground or hard-to-reach locations, providing continuous vibration insights for diverse infrastructure projects.